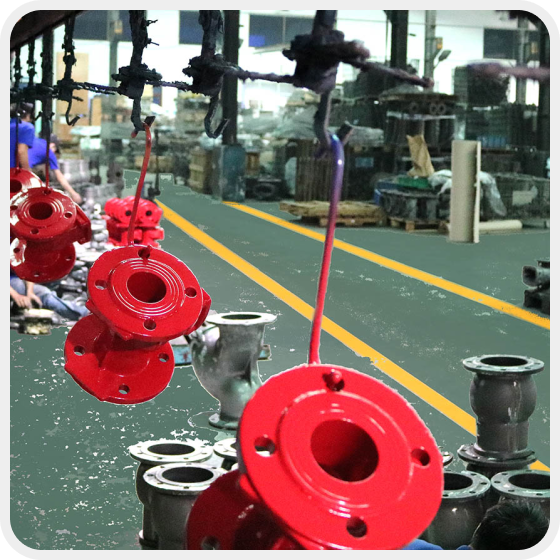

With its headquarters and factory situated in the Song May Industrial Zone, Bac Son Commune, Trang Bom District, Dong Nai Province, Shin Yi Valve Corporation was founded in 2005 as a result of cooperation between Taiwan and Vietnam. The company’s initial capital was more than $5 million USD.

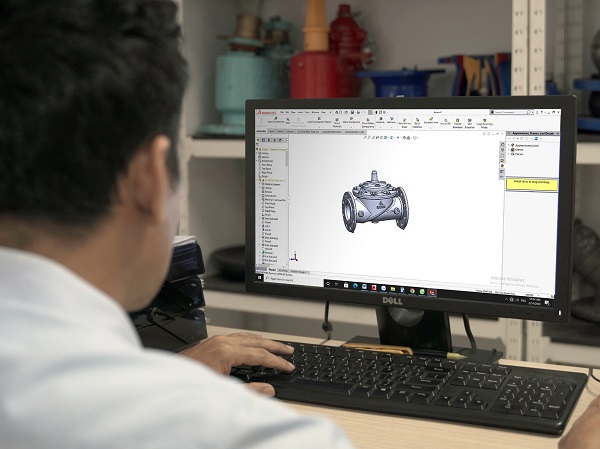

Shin Yi is now the only company in Vietnam that can fully manufacture a variety of industrial water valve lines thanks to a decade of technological and production line upgrades, as well as effective capital and human resource management. Shin Yi’s consistent progress is making the Vietnamese brand more prominent in the home market and extending its influence abroad.